Important attributes of gear oils

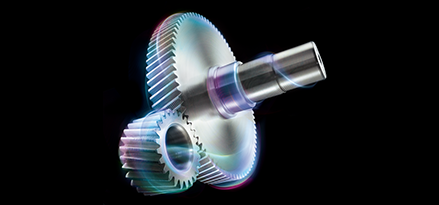

Cleanliness is critical when it comes to gear maintenance. As they are constantly in motion, the right lube will stay in the system for a more extended period, protecting the parts and improving their performance.

Durability is also an important consideration. Gearbox oils must be durable to ensure sustained performance over longer intervals of time. Along with that is a strong demulsibility, allowing gearboxes to be dried and cleaned easil. Our gearbox oils will be able to separate water quickly, even at extreme temperatures.

Lastly, for the lubricants to support the gearbox in extreme pressure conditions, it needs the right kind of oil additives in the optimum amount. The right combination of additives in the gear lube improves performance and maximizes efficiency.

How to choose gear oil

While choosing a gear oil for your equipment, you can make the right choice based on the following factors:

- Viscosity is one of the important properties of the lubricant. The gear units move against each other, and the viscosity of the oil ensures that it forms a thick layer between these moving units, preventing wear and tear. You can find the optimum grade of viscosity for your equipment in its user manual.

- Gear lube can be divided broadly into three categories based on the additives used - R & O, anti-scuff, and compounded. The right fit for your equipment will be based on its operating conditions. A combination of additives can be used to form the support required for the gear oil to deliver high performance and protection under extreme pressure conditions.

- Base oil selection is also crucial when choosing the lubricant. Based on your equipment’s needs, operating conditions, and type, you can select a mineral or synthetic-based lubricant. While minerals have higher pressure-viscosity coefficients, synthetics have greater resistance to thermal and oxidation corrosion. The higher viscosity grade of synthetics also enables performance delivery in extreme temperature conditions.

Your equipment’s operating conditions and application will determine what kind of viscosity, additives, and base oil it requires for its right protection.

Our range of gear oils is formulated with advanced lubrication technology that ensures your equipment’s best performance with maximum protection. Explore our lubricant products and choose the right fit for your equipment, or contact our experts for advice.

Lubricants for Gears

<%= raw.productdescription%>

<%= raw.marketindustrialproducttypeandfeature %> <% } else { %> <%= title ? title : '' %>

<%= raw.productdescription%>

<%= raw.marketindustrialproducttypeandfeature %> <% } %>

FAQs and tips

Additional gear applications

-

FAQs and tips

Get answers to the most common questions regarding maintenance, storage and application of our lubricants to help improve efficiency, productivity and safety.

Know more