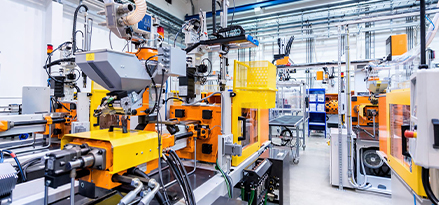

Manufacturing is all about efficient production, whether you’re making food, plastics or machine parts. Mobil℠ provides the lubrication solutions you need to enhance equipment life and reliability while minimizing maintenance downtime and costs. We support manufacturers with state-of-the-art expertise and services drawn from deep OEM relationships and more than 150 years of industrial experience. Our world-class Mobil™ synthetic and premium mineral-based oils and greases are designed to protect manufacturing equipment, helping plants run more productively and efficiently.

-

Products

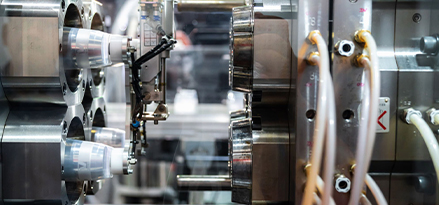

Explore our range of hydraulic oils, designed supreme performance over a wide range of temperatures, high level anti-wear properties, excellent detergency and keep-clean properties.

Learn more -

Services

Learn how Mobil™ Serv Lubricant Analysis can help provide your business with optimized maintenance.

Learn more