Description

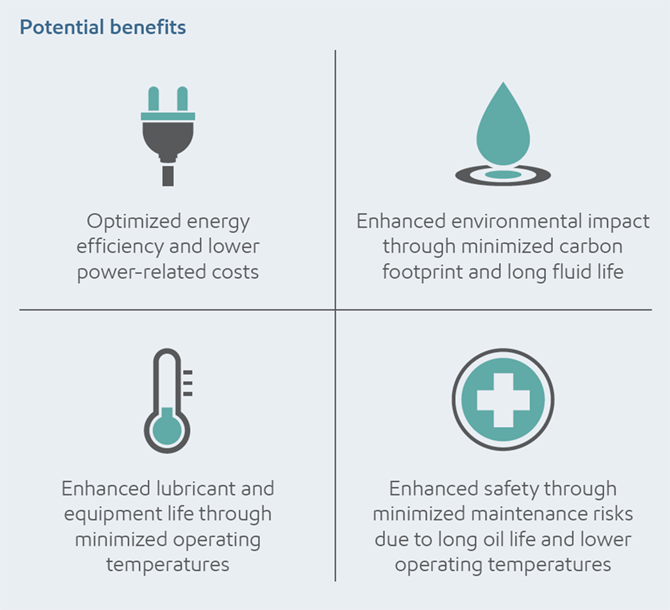

Highly trained ExxonMobil representatives work with you to explore how synthetic lubricant usage could help maximize energy efficiency – to minimize power-related costs, lessen your carbon footprint and extend fluid life (compared to conventional lubricants). They present the theory and application behind using lubricants that can provide energy efficiency benefits.

Highly trained ExxonMobil representatives work with you to explore how synthetic lubricant usage could help maximize energy efficiency – to minimize power-related costs, lessen your carbon footprint and extend fluid life (compared to conventional lubricants). They present the theory and application behind using lubricants that can provide energy efficiency benefits.

Application

We work with you to:

We work with you to:

- Determine objectives, expectations, focus and scope

- Coordinate and oversee pre-test, test and post-test work

- Involve and coordinate with appropriate plant personnel

- Develop detailed test protocol

- Respect all safety and labor rules and ensure complete confidentiality

- Document results and recommendations

Deliverable: An Engineering Service Report details the energy efficiency study’s results and estimates the value of its recommendations to help achieve efficiency and savings.

Common opportunity areas

- Identifying the optimum lubricants for energy efficiency benefits

- High operating temperatures

- Determining the potential energy saving objectives that will meet customer sustainability goals

Safety, health and environment

Our field engineers are attuned to the hazards of handling, storing and using petroleum products. They strictly observe safety and environmental rules, as well as ExxonMobil and customer safety practices. They coordinate efforts through designated plant personnel verifying electrical and mechanical lockout and proper tagging prior to working on equipment, and providing recommendations to help reduce hazards.