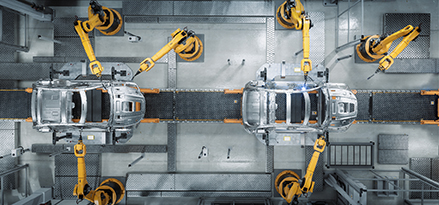

Manufacturing (Productivity)

'Expect the unexpected? Wouldn’t it be nice if you didn’t have to?'

Plant management, especially in the past two years, has stretched Southeast Asia’s manufacturers to their limits, demanding ever greater levels of flexibility. Rolling with the punches has been more bruising than ever and planning ahead has felt a lot like shooting in the dark. On a macro level this won’t change anytime soon. The predictions for the short term performance of the manufacturing sector in Southeast Asia seem to change month to month and so too does stakeholder confidence.

But longer term, few disagree that the scale of the opportunity is limitless if manufacturers in the region fully modernize their systems and processes. Boston Consulting Group has suggested that by 2030 the manufacturing sector could generate over US$600Bn additional output per year, increase annual FDI by up to US$22Bn, and create up to 140,000 new jobs every year1. The growth of the middle class in markets like Indonesia, the e-commerce boom and a thriving tech sector all suggest the region will intensify its challenge to China's manufacturing dominance.

A low wage workforce has long made Southeast Asia attractive for labor-intensive and low value-added manufacturing but to fulfill their potential organizations in the region must compete for more future-facing manufacturing processes. They must move beyond data-informed diagnostics, and instead embrace an advanced analytics cycle that includes both predictive and prescriptive analytics. Analytics that helps manufacturers get ahead of the unknown and respond fast with the right action.

From anticipating problems to reducing costs to mitigating risk to improving on the spot decision making, accessible data on demand will increasingly shape the plant management challenge. The clearest role for analytics in the manufacturing process is in the prediction of failures and the acceleration of response times. Cost savings from reduced machine downtime, elevated workforce productivity, reduced field service costs, improved safety and refined product/process design can be enormous in aggregate. These are cost savings that can either be held back to release margin pressures or reinvested in the further digitization of the manufacturing pipeline.

“Analytics will be central to the achievement of Manufacturing 4.0 in ASEAN”

However, predictive or even preventative maintenance is not where the opportunity ends. For plant managers the applications are endless. Analytics will be central to the achievement of Manufacturing 4.0 in Southeast Asia. Procurement strategies will be enhanced by a more accurate assessment of TCO (Total Cost of Ownership). Workforce management will be informed by a granular understanding of employee productivity. Quality control standards will be improved by data gleaned from smart devices at the edge.

But the journey from gathering data to applying it effectively can be a long one. Plant Managers and Maintenance Leads will have to radically redesign how they operate from upper management to delivery. The cleaning, management and governance of data across many units, processes and systems will be a massive challenge. Installing new IoT devices and integrating new systems with existing ones will require significant investment in people and, unlike in many other instances, approaching transformation in an ‘agile’ way is not an option.

Those tasked with improving productivity are searching for how to close the gap between ambition and achievement. They want to take steps towards data-enhanced productivity without disrupting current practices. The answer to this challenge lies in working with trusted partners who can help modernize your processes and systems bit by bit. Partners who share a belief that advanced analytics is both highly valuable and highly achievable. Partners like Mobil who are supporting Southeast Asia’s manufacturing leaders as they look to capitalize on the customer base and the tech sector in the region.

Mobil has been an innovator in the lubricants game for over 150 years. Our continuing investments in research and development have ensured our lubricants always deliver the highest performance in the market. But now we are pushing harder to give our customers an advantage in operational efficiency, proactive maintenance and material management by integrating advanced analytics services into our offering. We will continue to deliver the market leading formulations our customers rely on but also place data-driven intelligence on indicators like emulsion conditions, ph level and concentration trends in the palm of your hand - the perfect pairing as you look to get ahead of the unknown.

Citations

Sources

How Bad Is China's Manufacturing exodus? - Nikkei Asia, June 2022

Manufacturing & Sourcing in Southeast Asia: Industries, Trends, and Benefits - Asia Perspective, June 2022

Why Manufacturers Must Rethink Their Supply Chains In Southeast Asia - Ernst & Young, February 2022

Data and Analytics in Manufacturing: Overcoming Challenges - Tata Consultancy Services, March 2021

Applying Big Data Analytics On The Plant Floor - Vertech, August 2021

Predict Process Events With Contextual Data Insights - Plant Engineering, March 2022

A Closer Look At Southeast Asia’s Promising Manufacturing Industry - Tech Collective Asia, March 2022

Predictive Analytics in Manufacturing: Use Cases & Benefits - Vanti, 2021

Related content

-

No more off switch

How mobility is flipping the manufacturing model and putting the customer in control.

Learn more