Mobil SHC™ 629 synthetic circulating oil reduces costly blower-related downtime

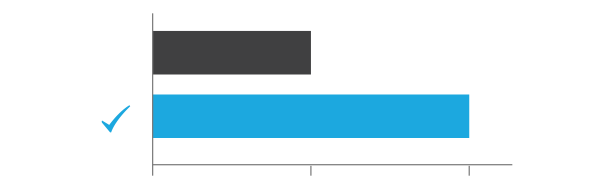

Overhaul intervals increased by

140%

Blowers Model GM 80L, 130L & 220L

Calidra de Oriente S.A. de C.V.

Acajete, Puebla, Mexico

Situation

The Calidra Ajacete mine has had to replace 34 blowers over the last 13 years. The blowers operate at high speeds in a dusty environment where temperatures often exceed 80°C (176°F). The OEM recommends oil drain intervals of 8,000 hours and overhaul intervals of 20,000 hours for the gear set and bearings. In an effort to improve equipment reliability, the company approached Lubricantes Especializados de Oriente S.A de C.V. (LEORSA), an authorized ExxonMobil distributor, to identify a lubricant solution capable of preventing unscheduled downtime.

Recommendation

LEORSA engineers recommended the company switch to Mobil SHC™ 629 synthetic circulating oil. Formulated with a combination of advanced synthetic base stocks and proprietary additives, Mobil SHC 629 circulating oil provides excellent resistance to oil breakdown in extreme temperatures. Additionally, the engineers recommended the company implement routine Mobil Serv℠ Lubricant Analysis to monitor equipment and oil life.

Result

After switching to Mobil SHC 629 synthetic circulating oil, the Calidra Ajacete mine was able to achieve 48,000 hours without an equipment overhaul, reducing maintenance workloads and related exposure of plant personnel to potential safety hazards. In addition, Mobil SHC 629 oil has helped reduce unscheduled and scheduled downtime. These reduced maintenance costs and improvements in productivity have generated company-estimated savings averaging more than US $82,000 per year.