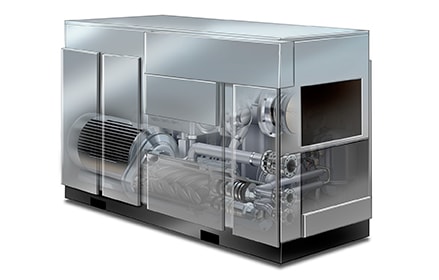

Air compressor maintenance

If you’re aiming to reduce the costs of compressing air in your plant, there are a few simple but important steps you can take. This article explains the three basic factors involved in the cost of producing compressed air, and then guides you through the steps you can take to effectively reduce your costs. The article demonstrates the importance of maintaining optimum operating temperatures, using the correct filters and lubricants, and cleaning your air cooling systems. You also learn why maintaining safe storage of reserve air is essential, as is delivering dry air at the intended pressure and minimizing air leaks. Power consumption and compressor maintenance make up as much as 90 percent of compressed air production costs. This article provides ways to cut those costs to boost the profitability of your operation.