Cutting and quench oil reclamation

This valuable service for cutting or quenching operations can help lower operational costs and boost revenue through establishing proper used oil collection and segregation practices, along with on-site oil purification.

Description

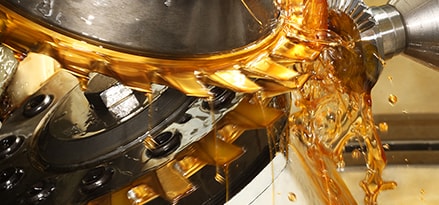

Expert engineers set up best practices for minimizing water to prevent foaming and irregular cooling and cutting rates, as well as to control sediment and particulate levels to help eliminate deposits. Used fluid is then purified at the facility and qualified for continued use.

Application

Expert engineers will work with you to:

- Determine performance goals to be achieved by the service

- Recommend segregation, collection and handling methods for used cutting or quench oil

- Establish guidelines for measuring the fluid’s suitability for continued use

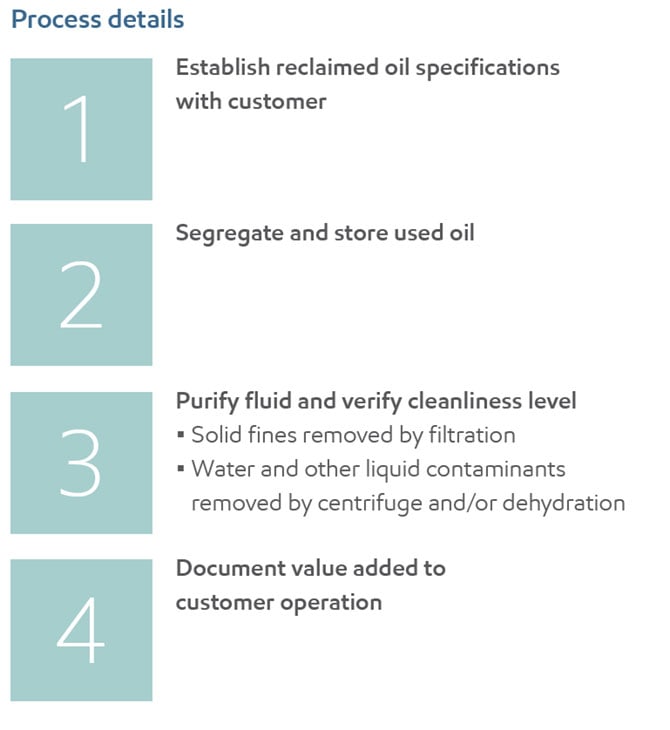

- Coordinate arrangements with the service technician who will:

- Complete the purification process

- Verify that fluid specifications are met or exceeded

- Gather key baseline and other relevant data

Deliverable: An Engineering Service Report details the fluid treatment steps completed, documents fluid cleanliness level prior to and after treatment, recommends steps to maintain fluid cleanliness and provides an estimated value of the service. Distribute and present the completed report to plant management and key personnel.

Common opportunity areas

- Elevated sediment or particulate levels

- Staining on parts

Safety, health and environment

Field engineers are attuned to the hazards of handling, storing and using petroleum products. They strictly observe safety and environmental rules and ExxonMobil and customer safety practices. They coordinate efforts through designated plant personnel verifying electrical and mechanical lockout and proper tagging prior to working on equipment, and providing recommendations to help reduce hazards.