Jim Hannon, Industrial Lubricants Technical Advisor, ExxonMobil Research and Engineering

In ExxonMobil’s The Outlook for Energy: A View to 2040, we predict a more than 100 percent increase in global demand for energy, as compared to levels in 2010. In the industrial sector, we can help mitigate the effects of this rising demand by improving the efficiency of our machinery and equipment.

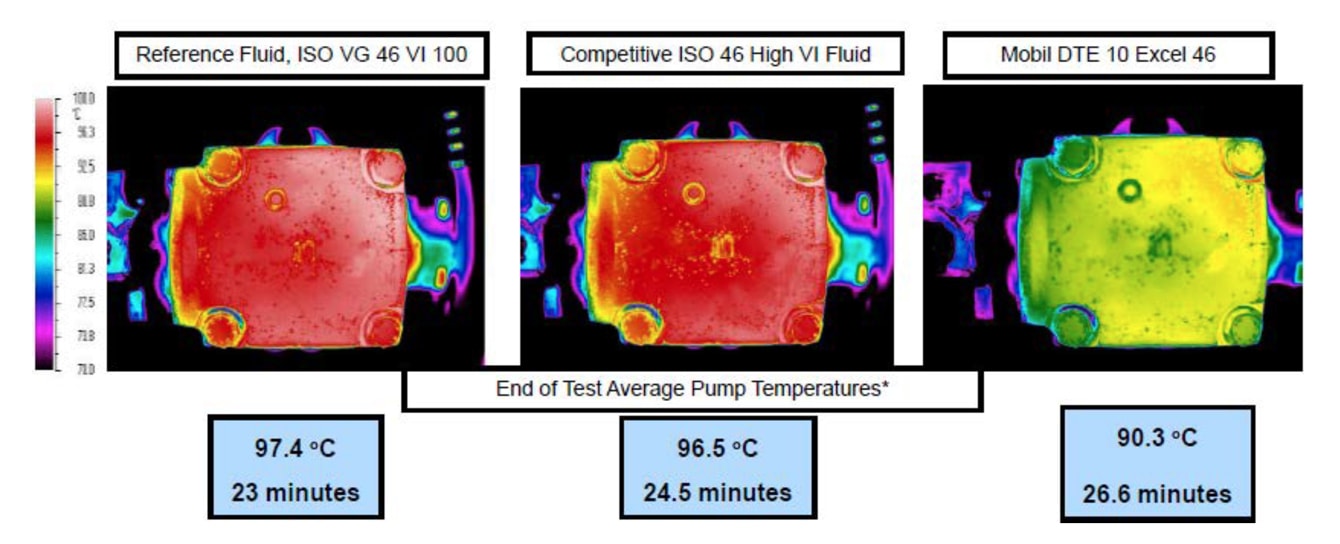

Through extensive research, we’ve found that using a lubricant formulated with base stocks that have low traction coefficients, which help to reduce frictional energy losses within industrial pumps, can decrease temperatures in machinery by up to 13°C.

A lubricant that enhances volumetric and mechanical efficiency will reduce friction within the pump and generate less heat. High temperatures, therefore, signal energy inefficiency. We used thermal imaging to compare lubricants in simple hydraulic circuits to determine their relative efficiency by comparing heat generation.

We tested three lubricants in simple hydraulic circuits without heat exchangers and used thermal imaging to show how Mobil DTE 10 Excel™ 46 can reduce frictional losses within pump systems.