Advanced lubrication training

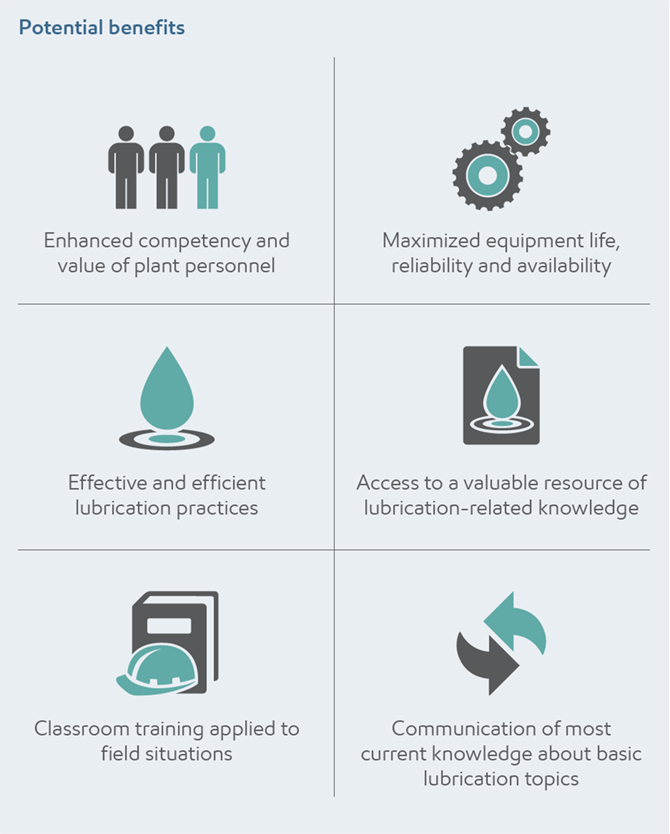

Thorough training sessions led by expert engineers can help plant personnel implement and manage more efficient and effective lubricant-related practices.

Description

Our experienced engineers conduct customized training sessions with plant personnel to potentially help improve operations. Drawing on their expertise, the engineers explain the impact of lubrication practices, adapting the training to meet your specific needs. Topics may include: hydraulics, gears, bearings, way lubrication, mobile equipment, storage and handling, and oil analysis. The sessions emphasize application and technical issues, as well as problem identification and resolution.

Application

We work with you to:

- Discuss potential training topics, timing and involvement

- Identify, select and extend invitations to clinic attendees

- Invite expert equipment builder and supplier resources when possible

- Develop the proposed agenda and identify all required resources

- Assist with invitations and implement follow-up process

- Present certificates to attendees (if applicable)

- Document attendance, significant outcomes and benefits

Deliverable: Our knowledgeable engineers present well-prepared and professionally delivered training on advanced lubrication topics. An Engineering Service Report or letter documents the event, outcomes and resulting value of the service. Certificates are issued to participants if the training is for competency certification.

Common opportunity areas

- Misapplication of lubricants

- High oil consumption

- Premature wear/failure of equipment

- Unscheduled downtime

- Improper storage and handling

Safety, health and environment

Our field engineers are attuned to the hazards of handling, storing and using petroleum products. They strictly observe safety and environmental rules, as well as ExxonMobil and customer safety practices. They coordinate efforts through designated plant personnel verifying electrical and mechanical lockout and proper tagging prior to working on equipment, and providing recommendations to help reduce hazards.