Mobil SHC™ 636 synthetic circulating oil helps paper mill extend oil life by 300 percent

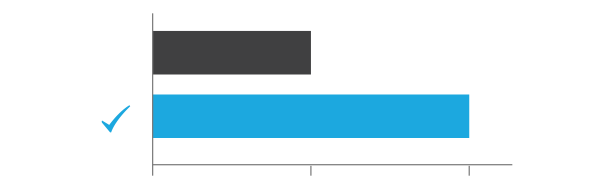

Extended oil drain intervals by

300%

Pulp mill lime kiln trunnion bearings

Pulp and paper producer

Ontario, Canada

Situation

An Ontario-based pulp and paper producer operates a pulp mill lime kiln, which operates at temperatures as high as 1,652°F (900°C) and is supported by trunnion bearings. Lubricated with a conventional mineral-based circulating oil, the trunnion bearings experienced heavy varnish and deposit buildup, which led to unscheduled downtime for cleaning, draining and refilling the bearings with lubricant. In an effort to extend oil drain intervals and reduce equipment downtime, the company approached ExxonMobil to identify a lubricant solution capable of delivering high performance under demanding operating conditions.

Recommendation

ExxonMobil engineers recommended the company switch to Mobil SHC™ 636 synthetic circulating oil. Mobil SHC 636 oil provides excellent resistance to oxidation and deposit formation at elevated temperatures, protection against rust and corrosion, as well as outstanding wear protection.

Result

After transitioning to Mobil SHC 636 synthetic circulating oil, the company was able to eliminate sludge formation in its trunnion bearings and cut oil change time from 16 to eight hours. Additionally, the company was able to reduce cooling-water consumption by 30 percent, and extend oil drain intervals by four times, significantly reducing oil demand and used oil disposal. These reduced labor- and equipment-related costs generated a company-estimated annual savings of more than US $100,000.