Conor Wilkinson, Industrial Field Marketing Advisor, ExxonMobil Fuels & Lubricants

A common practice for industrial operators is to employ service contracts with maintenance companies or equipment manufacturers to maintain certain items of equipment on site.

Some of the most widely used types of service contracts are those that cover compressor systems.

These contracts can have significant advantages, as the maintenance responsibility falls on the service company to guarantee availability of the equipment and maintain the manufacturer’s standard.

As part of some market research into the operation and lubrication of compressor equipment, ExxonMobil recently commissioned studies* across Europe to assess compressor maintenance strategies of several hundred industrial manufacturing sites.

The results from this survey identified some interesting trends. Some quick highlights include:

- Service contracts vs. self-maintenance: On average, more than 80 percent of companies said they trusted their compressor maintenance to service contracts, either with the Original Equipment Manufacturer (OEM) or a third party service provider. By comparison, less than 20 percent of sites maintained and operated compressor systems themselves.

- Age of compressors: A large majority of compressors in operation were more than five years old and out of the manufacturer’s warranty period, although companies still chose to use a service contract for maintenance.

- Oil drain intervals and maintenance practices: Most companies reported using the compressor manufacturers’ recommended lubricating oil, with the majority of sites (more than 66 percent) reporting that oil drain intervals spanned from 4000 to 8000 hours operation. Additionally, just one in four companies said they use periodic oil analysis to track equipment and lubricating oil condition.

Extreme operating environments highlight need for high quality lubricants

In modern compressors, lubricating oil is often subject to extreme operating conditions, including continuous high temperature operation in applications with discharge temperatures up to 200°C. Such occurrences of high temperatures, in addition to the presence of moisture in the compressed air, can lead to rapid oil oxidation, which can reduce oil life and cause problematic system deposits. For mineral compressor oils or lower quality synthetics, this means that operators must perform oil changes on an annual basis – or often more frequently – to maintain system integrity.

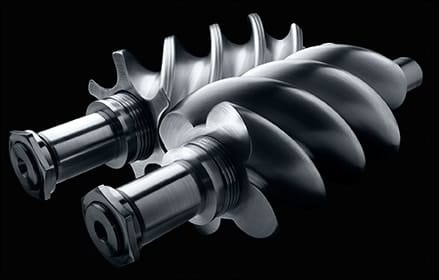

To combat these conditions and provide maximum oil life in rotary screw compressor applications, ExxonMobil recently introduced its most advanced synthetic compressor oil – Mobil SHC™ Rarus.

During extensive laboratory and real-world testing, Mobil SHC Rarus Series oils have shown the ability to deliver outstanding protection against wear, rust and corrosion, even under extended drain interval periods that range from two to three times longer than competitive synthetic oils.

Mobil SHC Rarus Series oils have even demonstrated the capability to last up to 24,000 hours in a compressor field trial (equivalent to 3 years of continuous operation).†

The images below show the effects of lubricating oil varnishing due to oxidation on the compressor screw component in comparative compressor rig tests.‡ See that even after 2500 hours of operation, Mobil SHC Rarus Series oils show considerably fewer varnish deposits than a competitive synthetic product, after just 1000 hours.

Do you know which lubricant is used in your compressor systems?

You may be able to make considerable savings in your operating costs or service contract by changing to longer life compressor oil, increasing the oil drain interval by up to three times and significantly reducing associated equipment downtime and cost of oil changes.‡

*research background: exxonmobil studies cited in this article were conducted in partnership with findlay media, a leading uk-based business media company for the manufacturing and engineering industry, and phocus marketing group, nuremberg, germany. in total, select personnel from nearly 350 manufacturing sites participated.

†proprietary compressor rig test, allows evaluation of candidate formulations in real world equipment with reduced cycle time, as there are no industry standard tests available. fluid performance is evaluated in a commercial oil-flooded rotary screw air compressor, with modifications to increase severity. oil life in compressor test gives relative indication of expected field performance. result relates solely to fluid performance in one rotary screw compressor. performance will vary based on operating conditions and application.

‡for equipment under oem warranty, consult with manufacturer before changing compressor oil.