Oil system preventive maintenance

Expert engineers provide a thorough system inspection and lubricant purification to help you reduce operational costs and maximize equipment productivity.

Description

Contaminated oil reservoirs – due to component wear, oxidation and/or external sources – can undermine the performance of your equipment and even lead to component failure. To help you avoid costly downtime for maintenance and repair, our experienced, well-trained engineers inspect and clean your oil system, as well as purify the lubricant in the system if it is deemed fit for continued use.

Application

Expert engineers will work with you to:

- Assist in the implementation of best lubrication management practices

- Inspect oil systems and make recommendations for optimizing reliability

- Help coordinate scheduling of service concurrent with planned downtime

- Help coordinate with the on-site provider to:

- Clean system reservoir in accordance with site procedures

- Gather key baseline and other relevant data

Deliverable: An Engineering Service Report details the cleaning steps completed, documents the cleanliness level prior to and after treatment, recommends steps to maintain cleanliness and other appropriate services and provides an estimated value of the service. Distribute and present the completed report to plant management and key personnel.

Common Opportunity Areas

- Reservoir sediment

- Valve sticking

- Performance issues

Safety, health and environment

Field engineers are attuned to the hazards of handling, storing and using petroleum products. They strictly observe safety and environmental rules and ExxonMobil and customer safety practices. They coordinate efforts through designated plant personnel verifying electrical and mechanical lockout and proper tagging prior to working on equipment, and providing recommendations to help reduce hazards.

Mobil Serv Lubrication Analysis: A simple way to cut costs.

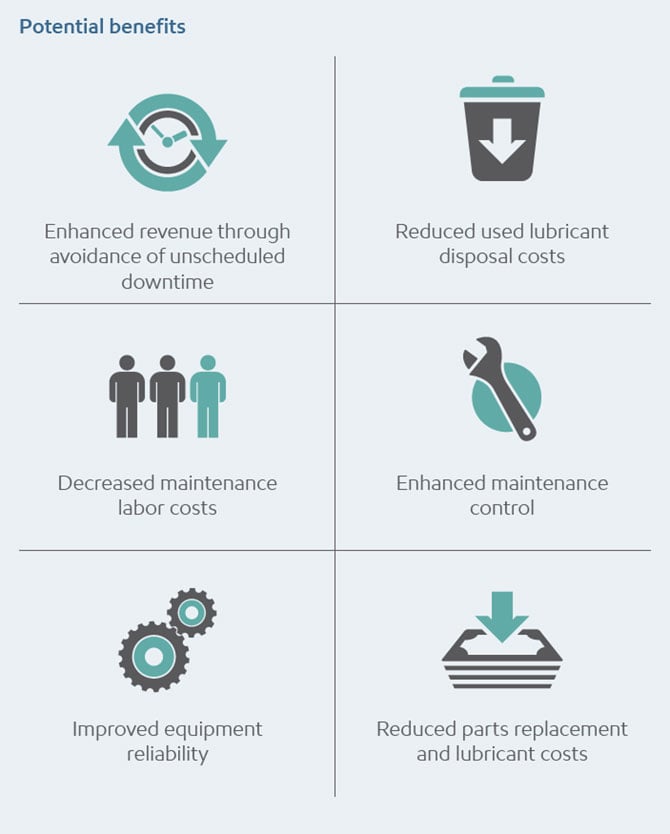

A regular lubricant analysis program can save thousands a year –while giving deep insight into how to maximize the life of your lubricants and a broader understanding of equipment performance.

Mobil Serv℠ Lubricant Analysis (MSLA) delivers a full spectrum analysis of your current lubricants, which no other service can provide.

In conjunction with MSLA, our Mobil Serv engineers can help you find the optimal interval for when to change the oil – often leading to longer drains allowing you to maximize the benefits of our products.

Sign up for a free trial today to see how MSLA can help your business .