Wind energy

There’s a reason so many companies trust Mobil industrial lubricants to keep their wind turbines spinning. We deliver optimum equipment protection and oil performance in a wide range of conditions, including onshore, offshore, dry or wet, and at high or low temperatures.

Mobil lubricants have helped power generation facilities around the world take their uptime, efficiency and productivity to the next level, and we’re excited to expand on what we already offer the wind sector with our top-of-the-line products and engineering services

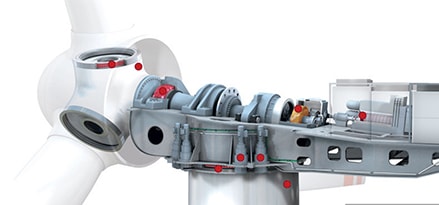

If you work in wind power, you already know about the unique challenges we face: the care and maintenance required of any turbine is complicated by the fact that this technology is exposed to extreme weather conditions and, of course, live hundreds of feet off the ground. Embarking into that world effectively requires extensive planning and precisely engineered products and machinery — which is right where we come in.

We also offer Mobil℠ Engineering Services – including Wind Turbine Gearbox Flush and Fill, as well as startup and cleanliness guidance – which help support wind farm operators in achieving outstanding equipment protection and long service intervals, resulting in safety, environmental and operating cost benefits.

Onshore or offshore, you can count on our technology leadership and application expertise to help keep your wind turbines running at peak efficiency.

Lubrication services

Our skilled engineers provide hands-on guidance and application expertise through lubrication services that include Wind turbine flushing and filtration, as well as startup and cleanliness guidance.

To help you monitor lubricant and equipment condition, and avoid unscheduled maintenance, we offer Mobil℠ Lubricant Analysis, including a program specifically tailored to wind turbine applications.

Learn more about lubrication servicesFind out more about how we can help your wind operation.

-

Technical Resources