Advanced synthetic lubricants for high temperatures

Mobil SHC™ Elite synthetic oils are specially formulated to protect equipment operating at high temperatures or subject to temperature spikes. Even under these conditions, Mobil SHC Elite oils maintain outstanding performance up to:

- 12 times as long as mineral-based oils

- Twice as long as Mobil SHC™ 600 series synthetic oils

Advanced synthetic lubricants for high temperatures

Long-lasting, step-out performance

Specially formulated to protect equipment operating at high temperatures or subject to intermittent temperature spikes, Mobil SHC™ Elite oils maintain outstanding performance up to:

- 12 times as long as mineral-based oils

- Twice as long as Mobil SHC™ 600 series synthetic oils

Mobil SHC Elite oil provides protection:

- In continuous service up to 130ºC

- During temperature spikes up to 150ºC

- In temperatures as low as -45ºC

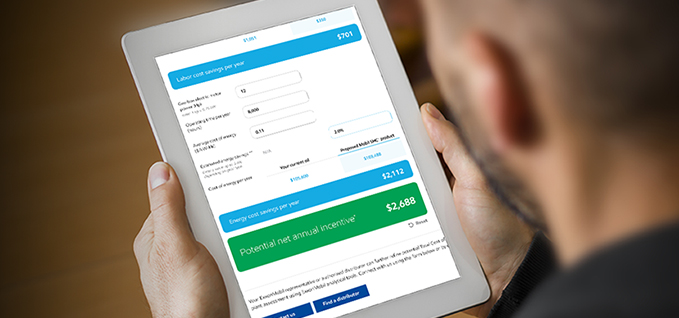

Add up your savings

Use our calculator tools to estimate your operation’s potential savings for upgrading your conventional lubricant to Mobil SHC™ oil or grease. Then contact an ExxonMobil engineer or authorized dealer to further refine your estimate.

Use calculatorProduct series information

Mobil SHC™ Elite Series offers {1} lubricant grades

<%= raw.productdescription%>

<%= raw.marketindustrialproducttypeandfeature %> <% } else { %> <%= title ? title : '' %>

<%= raw.productdescription%>

<%= raw.marketindustrialproducttypeandfeature %> <% } %>

Product Description

Mobil SHC™ Elite Series lubricants are exceptional performance circulating, gear and bearing oils designed to provide outstanding service in terms of oil drain intervals, equipment protection, oil life and problem-free operation helping to enable increased customer productivity. These scientifically engineered oils are formulated using the latest proprietary and patented Mobil SHC technology to provide outstanding and balanced performance in demanding applications at high temperatures.

Mobil SHC Elite Series products have demonstrated up to 3.6% improvement in energy efficiency in controlled laboratory testing(*). Mobil SHC Elite Series formulation also provides exceptional resistance to oxidation and deposit formation at elevated temperatures.

(*) Energy efficiency relates solely to the performance of Mobil SHC Elite when compared to conventional (mineral) reference oils of the same viscosity grade in gear applications. The technology used allows up to 3.6% efficiency compared to the reference when tested in a worm gearbox under controlled conditions. Efficiency improvements will vary based on operating conditions and application.

Features and Benefits

The Mobil SHC brand of lubricants are recognized and appreciated around the world for their innovation and outstanding performance. The development of Mobil SHC Elite Series was preceded by close contacts between our scientists and application specialists with key Original Equipment Manufacturers (OEMs) to ensure that the products provide exceptional performance in the continually evolving industrial equipment designs.

• Outstanding thermal / oxidation stability help to provide up to two times oil life** versus a leading a leading synthetic gear and circulating oil and reduce maintenance downtime

• Excellent deposit and varnish control helps to deliver cleanliness and extended oil and filter life

• High performance synthetic base stocks with high viscosity index enables wide temperature range capability and effective lubrication at high temperatures

• High load carrying capability protects equipment and extends life, helps minimize unexpected downtime and extend service periods

• Excellent resistance to rusting and corrosion, very good antiwear, demulsibility, foam control and air release

• Excellent seal compatibility helps reduce contamination and leakage

** Up to 2x oil life as demonstrated in numerous bench and rig tests. Oil life will vary based on application and operating conditions.

Applications

Mobil SHC Elite Series lubricants are recommended for use in a wide variety of circulating, gear and bearing applications where high temperatures are encountered or where operating temperatures or bulk oil temperatures are such that conventional lubricants give unsatisfactory life, or where improved efficiency is desired. They are particularly effective in applications where the maintenance costs of component replacement, system cleaning and lubricant changes are high. Specific applications require selection of the appropriate viscosity grade and include:

• Filled for life gearboxes, especially high ratio/ low-efficiency worm gears

• Remotely located gearboxes, where oil change-out is difficult

• Mixer roll bearings and roll neck bearings where high temperatures are encountered

• Plastic calendars

• Severe centrifuge applications, including marine centrifuges

• Mobil SHC Elite 150 and 220 are suitable for Oil Flooded Rotary Screw Compressors compressing natural gas, field gas gathering, CO2 and other process gasses used in the natural gas industry

Specifications and Approvals

|

This product has the following approvals: |

150 |

220 |

320 |

|

Fives Cincinnati P-59 |

|

|

X |

|

Fives Cincinnati P-74 |

|

X |

|

|

Fives Cincinnati P-77 |

X |

|

|

|

This product meets or exceeds the requirements of: |

150 |

220 |

320 |

|

AGMA 9005-F16 |

X |

X |

X |

|

DIN 51517-2:2018-09 |

X |

X |

X |

|

DIN 51517-3:2018-09 |

X |

X |

X |

|

ISO L-CKD (ISO 12925-1:2024) |

X |

X |

X |

Properties and Specifications

|

Property |

150 |

220 |

320 |

|

Grade |

ISO 150 |

ISO 220 |

ISO 320 |

|

Appearance, AMS 1738 |

Clear & Bright |

Clear & Bright |

Clear & Bright |

|

Copper Strip Corrosion, 24 h, 121 C, Rating, ASTM D130 |

2A |

2A |

2A |

|

Density @ 15.6 C, g/ml, ASTM D4052 |

0.870 |

0.872 |

0.873 |

|

Emulsion, Time to 37 mL Water, 82 C, min, ASTM D1401 |

30 |

30 |

30 |

|

FE8 wear test, V50 roller wear, mg, DIN 51819-3 |

2.5 |

1.5 |

|

|

FZG Scuffing, Fail Load Stage, A/8.3/90, ISO 14635-1 |

12 |

13 |

13 |

|

Flash Point, Cleveland Open Cup, °C, ASTM D92 |

266 |

272 |

278 |

|

Foam, Sequence I, Stability, ml, ASTM D892 |

0 |

0 |

0 |

|

Foam, Sequence I, Tendency, ml, ASTM D892 |

2094 |

20 |

20 |

|

Foam, Sequence II, Stability, ml, ASTM D892 |

0 |

0 |

0 |

|

Foam, Sequence II, Tendency, ml, ASTM D892 |

50 |

50 |

50 |

|

Foam, Sequence III, Stability, ml, ASTM D892 |

0 |

0 |

0 |

|

Foam, Sequence III, Tendency, ml, ASTM D892 |

50 |

50 |

50 |

|

Kinematic Viscosity @ 100 C, mm2/s, ASTM D445 |

18.7 |

26.6 |

33.7 |

|

Kinematic Viscosity @ 40 C, mm2/s, ASTM D445 |

150 |

220 |

320 |

|

Pour Point, °C, ASTM D5950 |

-36 |

-33 |

-33 |

|

Rotating Pressure Vessel Oxidation Test, min, ASTM D2272 |

2094 |

2075 |

1844 |

|

Rust Characteristics, Procedure B, ASTM D665 |

PASS |

PASS |

PASS |

|

Turbine Oil Stability Test, Life to 2.0 mg KOH/g, h, ASTM D943 |

10000 |

10000 |

10000 |

|

Viscosity Index, ASTM D2270 |

140 |

146 |

150 |

Health and Safety

Health and Safety recommendations for this product can be found on the Material Safety Data Sheet (MSDS) @ http://www.msds.exxonmobil.com/psims/psims.aspx