Mobil SHC PF 462

High Temperature Grease

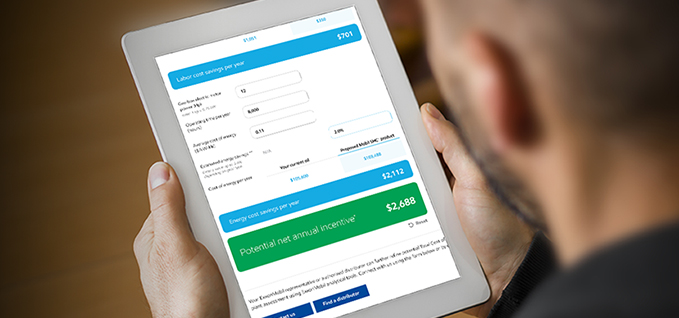

Add up your savings

Use our calculator tools to estimate your operation’s potential savings for upgrading your conventional lubricant to Mobil SHC™ oil or grease. Then contact an ExxonMobil engineer or authorized dealer to further refine your estimate.

Data sheets

Features and Benefits

Mobil SHC PF 462 provides dependable performance up to 240 ˚C (464 ˚F). Mobil SHC PF 462 provides excellent lubricity, corrosion resistance, thermal and oxidative stability and chemical inertness.

Mobil SHC PF 462 is non-flammable and highly resistant to oxidative degradation at temperatures up to 240 ˚C (464 ˚F). The high-temperature stability provides bottom line savings from improved reliability and reduction in grease usage and manpower through extended re-lubrication intervals.

Mobil SHC PF 462 is resistant to attack by chemicals and contaminants, including hydrocarbon oils, alcohols, acids, and caustic.

- Superb High-Temperature Stability

- Dependable performance at high temperatures

- Resistance to chemicals, caustics and solvents *

* Testing should be conducted to verify resistance before use in intended service. Not intended for pressurized oxygen service without testing and validation by the equipment builder and intended operator.

Applications

Mobil SHC PF 462 is engineered to provide excellent performance for a wide variety of demanding high-temperature applications including those found in the textile, steel, aluminum rolling, automotive, aerospace and forest product industries.

Mobil SHC PF 462 is compatible with other PFPE/PTFE greases, but should not be used with typical mineral or synthetic greases.

Properties and Specifications

|

Property |

|

|

Grade |

NLGI 2 |

|

Base Oil Viscosity of Greases @ 100 C, mm2/s, AMS 1697 |

42 |

|

Base Oil Viscosity of Greases @ 40 C, mm2/s, AMS 1697 |

440 |

|

Color, Visual |

White |

|

Copper Strip Corrosion, Rating, ASTM D4048 |

1B |

|

Corrosion, Bearing, Rating, ASTM D1743 |

PASS |

|

Dropping Point, °C, ASTM D2265 |

258 |

|

Flash Point, Base Oil, °C, ASTM D92 |

Does not ignite |

|

Four-Ball Extreme Pressure Test, Weld Point, kgf, ASTM D2596 |

800 Pass |

|

Four-Ball Wear Test, Scar Diameter, mm, ASTM D2266 |

0.58 |

|

High-Temperature Wheel Bearing Test, Leakage, g, ASTM D4290 |

0.5 |

|

Oil Separation, mass%, ASTM D1742 |

1.08 |

|

Oxidation Induction Time(PDSC), Minutes to Induction, 210 C, minutes, ASTM D5483 |

No Induction |

|

Roll Stability, 0.1 mm, ASTM D1831 |

2.7 |

|

SKF Emcor Rust Test, Distilled Water, ASTM D6138 |

0,0 |

|

US Mobility @ 0F, g/min, AMS 1390 |

7.4 |

|

Water Sprayoff, Loss, %, ASTM D4049 |

5 |

|

Water Washout, Loss @ 79 C, wt%, ASTM D1264 |

0.94 |

Health and safety

Health and Safety recommendations for this product can be found on the Material Safety Data Sheet (MSDS) @ http://www.msds.exxonmobil.com/psims/psims.aspx

- Corrosion protection

- High temperature

- Oxidation resistance

- Severe operating conditions